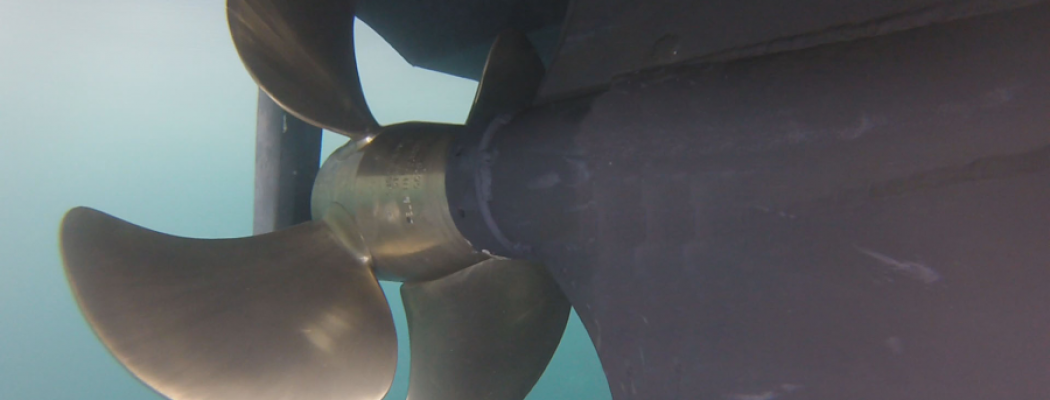

The Process of Condition-Based Cleaning for Propellers

Condition-based cleaning of propellers revolutionizes maintenance practices by determining the optimal time for cleaning based on the actual condition of the propeller. This data-driven approach maximizes effectiveness and reduces costs. Let’s explore the key steps involved in the process of condition-based cleaning for propellers.

Visual inspections and monitoring form the foundation of condition-based cleaning. Regular visual inspections are conducted every six months to assess the rate at which marine fouling accumulates on the propeller blades. These inspections provide valuable insights into the current condition of the propeller and serve as a basis for determining cleaning intervals.

Collaboration with the leading technology provider VPS plays a vital role in the process. VPS´ Maress software allows for the collection of relevant vessel data and the visualization of fuel consumption and emissions in operation. As part of the analytics, Maress is able to evaluate the impact of propeller cleaning on vessel performance. With this insight, ship operators can make informed decisions regarding cleaning intervals.

Data analysis is a critical component of condition-based cleaning. Propeller pictures taken at regular intervals are compared against the BIMOC standard for marine fouling, enabling the tracking of fouling development over time. In addition to visual data, other factors such as the last dry docking, previous hull cleaning, and the current season are considered to determine the optimal cleaning time.

Based on the analysis of visual data and other relevant factors, ship operators can make data-driven decisions regarding propeller cleaning. This ensures that cleaning is performed precisely when needed, optimizing vessel performance, and reducing fuel consumption.

Continuous collaborative development is ongoing in the field of condition-based cleaning. VUVI is actively working with supply ship companies and Maress from VPS to refine and enhance the procedures. Leveraging technology, data analysis, and industry expertise, these partnerships aim to further improve the effectiveness and efficiency of propeller maintenance.

The process of condition-based cleaning for propellers involves visual inspections, data analysis, and collaboration with technology providers. By leveraging these approaches, ship operators can determine the optimal time for propeller cleaning, maximizing efficiency and reducing costs. The ongoing collaborative development in this field holds promise for further advancements in propeller maintenance practices.

Contact us today to learn more about Condition-based cleaning of propellers.